how to measure tubing wall thickness|tubing wall thickness pressure chart : exporter exporters exporting DN vs. NPS: Compare Nominal Diameter (DN) with Nominal Pipe Size (NPS), unraveling the logical relationship for sizes NPS=4 and larger. Pressure Design Calculation: Learn the intricacies of . Resultado da Assistir capetinhas.blog gratis loira do Instagram Tiktor rebolando calcinha fio dental. Sarah Estanislau (@sarah.estanislau) loira linda e maravilhosa .

{plog:ftitle_list}

Resultado da 20 de abr. de 2023 · Telefone da TIM. Se quer falar com a operadora TIM, deve ficar atento ao assunto que você deseja tratar e a qual serviço se refere.São essas duas condições que vão definir qual o número do telefone da TIM para falar, por exemplo, com o TIM Live Suporte.Além de ligar .

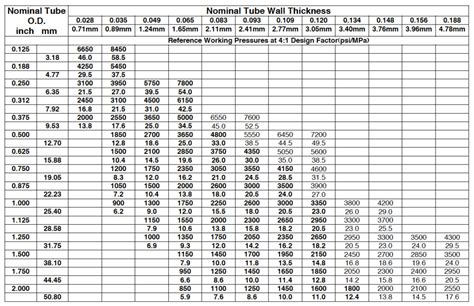

tubing wall thickness pressure chart

DN vs. NPS: Compare Nominal Diameter (DN) with Nominal Pipe Size (NPS), unraveling the logical relationship for sizes NPS=4 and larger. Pressure Design Calculation: Learn the intricacies of .

tubing wall thickness gauge chart

Determine the wall thickness of the tubing. Nominal Recovered Wall Thickness – The target thickness of the wall after complete recovery. The Wall Thickness of the tubing is measured in inches (in.) or millimeters (mm). Ultrasonic thickness measurement, magnetic particle inspection, radiographic testing, and optical profiling are some of the most frequently used techniques for determining a pipe's wall thickness. The thickness of the .

Plug the two numbers into the following formula: (Diameter of Outer Wall - Diameter of Inner Wall)/2. The resulting number is the thickness of the pipe wall. The Drip Cap. Pipes are divided into different categories based on both length . Using a thickness gauge is the most reliable and accurate method to measure this parameter. Whether it's ultrasonic, electromagnetic, or mechanical, these specialized tools enable professionals to precisely . Tube is measured and referred to according to its outer diameter and gauge, meaning its wall thickness. Common gauges include 10, 11, 12, 13, 14, 16, 18 and 20. The .

A pipe's wall thickness measurement is crucial for quality assurance and safety purposes. The size, composition, and location of the pipe are only a few of the variables that affect the thickness measurement .

Switch out anvils depending on the shape of the item you're measuring. Use the rounded anvil to measure the wall thickness of pipe, tubing, and other curved surfaces. Use the flat anvil to measure flat surfaces.. This micrometer has a friction thimble with a constant-force mechanism, so that once the spindle contacts the surface of the measured object, it will stop tightening. Having the inside dimensions (ID) and the outside dimensions (OD) will allow you to figure out the wall thickness on the tubing. You would need to subtract the ID from the OD and then divide by two. This number is the wall thickness. For example: Item# 59001 has an ID of 1/8" and an OD of 3/16". Subtract 3/16" - 1/8" = 1/16".

tubing wall thickness chart

tubing gauge thickness chart

custom general pin type moisture meter

This will keep you from accidently compressing the tubing and getting a false, low reading. Wall thickness should only be measured on fully recovered tubing. You start by recovering a sample in an oven or heat gun and letting it cool until you can handle it with your hands. Then measure the ID and OD as above. Average wall thickness can then easily

accidently compressing the tubing and getting a false, low reading. Wall thickness should only be measured on fully recovered tubing. You start by recovering a sample in an oven or heat gun and letting it cool until you can handle it with your hands. Then measure the ID and OD as above. Average wall thickness can then easily be calculated

An inline wall thickness measurement system at the output end of a forming mill in a seamless steel tube production line is illustrated in Figure 2. It has a measurement head that contains beam delivery optics for the pulsed ultrasonic-generating laser, together with sensor optics for the remote, fiber-coupled CW laser ultrasonic receiver. We show the traditional method for measure roll cager tubing thickness using a caliper and using an ultrasonic thickness gauge that does not require drilling.

For instance, let’s say you wrapped your lucky shoelace around the pipe and marked the circumference on the shoelace. Comparing your shoelace to a measuring tape, you found the length of the string circumference is almost 7-1/2″.. 7-1/2″ ÷ pi (or 3.1415) = 2.38″ Outside Diameter. Wall Thickness: Measure the thickness of the pipe’s walls. This step is crucial for accurate fittings and connections. Nominal Diameter (DN): For HDPE and PEX pipes, understand the nominal diameter and how it relates to their applications. Thread Size: Use a pipe thread size chart to match the fittings and connections with the pipe thread size.

PosiTector UTG Ultrasonic Wall Thickness Gauges measure the remaining wall thickness of materials such as steel, plastic and more using ultrasonic technology. Ideal for measuring the effects of corrosion or erosion on tanks, pipes, or any structure where access is limited to one side. Select from corrosion, low frequency, precision, and multiple echo thru-paint models.The Wall Thickness of the tubing is measured in inches (in.) or millimeters (mm). Refer to the tubing’s Technical Data to determine the thickness of the wall. 4.tube from the outside of the wall rather than the inside. Wall Thickness / Gauge - Two ways of measuring the thickness of the tube’s wall. Wall thickness is commonly measured in inches or millimeters, while gauge is a standard integer. e.g. 0.049 inch wall thickness = 18 gauge

7.2.6 Determine the minimum remaining wall thickness measurement for each grading unit. 7.2.7 The minimum remaining wall thickness for each Grading Unit shall be recorded on the API Thickness Measurement Report Form. 7.2.8 Determine the Grading Unit Flaw Category for each grading unit. See figure 2 for a list of Grading Unit Flaw Categories.The measurement of the SS Tubing Sizes between the interior and exterior of the tube is called the wall. This is utilized in measuring the thickness and the overall strength of the tube. Designed without any welds a Seamless Stainless Steel Tubing Size Chart covers tubes in sizes between 0.84 inches to 4 inches. The wall thickness of these . How To Measure Metric Tubing? Measuring metric tubing accurately ensures proper functionality and compatibility. Follow these steps for precise measurements: Use a caliper or micrometer for precise .

Use a tape measure across the pipe's width to determine the size. A simple way to measure a pipe's diameter is to use a tape measure across the width of the pipe. This gives you the size quickly without specialized tools. It's . Wall thickness measurement with ultrasound is useful wherever the measuring point is only accessible from one side and a caliper gauge cannot be used.The inn. Measuring Thickness of Pipe Measure the overall diameter with a tape measure and record this number on a pad of paper. This is the measurement completely across the top of the pipe from outside to outside. Next, measure the inside diameter of the pipe with the same measuring instrument. This is from the inside wall across to the other inside wall.

It involves determining the wall thickness — the measurement between the outside diameter (OD) and inside diameter (ID) of a tube — at different points to see how constant it is in relation to a central axis. . More simply put, you can define concentricity as a measure of the constancy of the wall thickness of a tube, pipe, or other .

Measuring Wall Thickness for Small Metal and Plastic Tubing . such as single or multilayer diameter tubing with wall thickness down to 0.001 in. (25 μm). To efficiently couple sound energy into small-diameter test pieces, inspectors must focus the sound beam into a very small spot. When diameters are under approximately 3 mm (0.125 in .

An inadequate wall thickness can lead to catastrophic failures, leaks, and potentially hazardous situations. To ensure the safety and efficiency of any pipe system, it is crucial to have an accurate measurement of its wall thickness. Understanding Wall Thickness Gauges. Ultrasonic gauges are widely used for non-destructive testing of pipe walls.Note-2: t = Nominal wall thickness. D = Outside diameter. Note-3: For welded pipe, the weld area shall not be limited by the over tolerance. Note-4: For thin-wall pipe, the ovality in any one cross-section shall not exceed 1.5 % of the specified outside diameter. Click on the Below Image to get your Printable Pipe Size Chart.

If you’re looking to measure the thickness of a pipe, an ultrasonic thickness gauge should be used. A handheld thickness gauge, such as the 27MG gauge, will offer accurate measurements from one side of metal pipes and parts that are thinning due to erosion or corrosion. . Learn how to measure the wall thickness of commercial glass products .This will keep you from accidently compressing the tubing and getting a false, low reading. Wall thickness should only be measured on fully recovered tubing. You start by recovering a sample in an oven or heat gun and letting it cool until you can handle it with your hands. Then measure the ID and OD as above. Average wall thickness can then easilyA pipe's wall thickness is especially important to know during construction projects, as a pipe with too thin a wall may burst under pressure. . Place your ruler or measuring tape over the mouth of the pipe. Measure the diameter of the pipe from the top of the outer wall to the bottom of the outer wall. Note this down on a piece of paper.

Jin et al. proposed a tubing wall-thickness measurement method based on a measurement sensor and designed an online tubing wall-thickness measurement system with a wall-thickness measurement accuracy of ±0.05 mm. The indirect measurement method is mainly based on the principle of eddy current measurement and ultrasonic measurement, .Our gauges are used all over the world for thickness measurement of storage tanks, pipe wall, cast iron parts, plastics, alloys and more. Have a special application? . Measure cylinder wall thickness, deck height, chassis tubing & more. View Category. ZX-1. Manually adjust velocity to calibrate to any material type. Resolution:.001" (0.01 mm)

steel tubing wall thickness chart

standard tubing size chart

webCosplay de Bulma usando roupa de coelhinha mas mostrando sua buceta e seus peitos enormes! Garotas lindas e gostosas fazem Cosplay da Bulma de Dragon Ball Z e a personagem parece uma mulher de carne e osso. Assim vemos a Bulma da vida real nua como veio ao mundo mostrando as belas tetas e sua linda bucetinha!Aqui você confere .

how to measure tubing wall thickness|tubing wall thickness pressure chart